We recently purchased a new machine -the L12 X – to add to our 12mm section, increasing capacity in this sector by 50%.

We were able to go from space in our workshop to machining parts to dispatch within 5 days!

Machine specification:

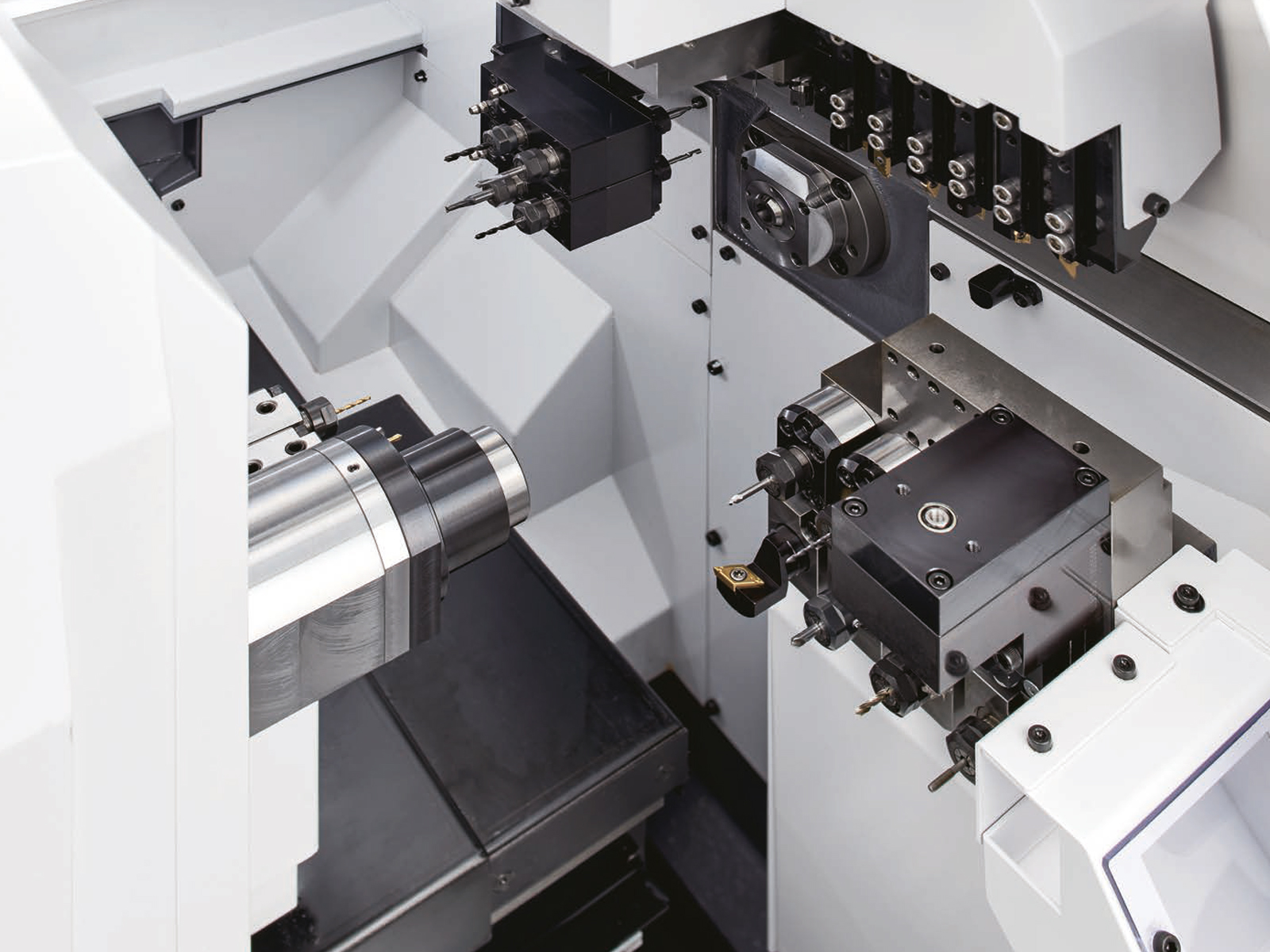

The L12 X has a wide variety of tooling layouts available, such as “adjustable angle end-face spindle” (B-axis) which allows for angled hole drilling and enables us to perform various kinds of machining. It is equipped with a Y2 axis to the back spindle offering greater flexibility of up to 8 tool stations for secondary machining. This increases the degree of freedom for process allocation, and increases the maximum number of tools that can be installed to 38 (of which 11 are cross and face driven). Main and sub spindle can ramp up to 12000 revs per minute (rpm), the face and driven tools max rpm is 10000.

This L12 is also fitted with high pressure coolant, the machine can run without a guide bush and has a 4 meter Iemca bar feeder for unattended machining. Quick cycle times offer higher yield rate on complex components.

Contact us if you have components you think would suit this application on info@sub-cncprecision.co.uk or use our contact form here.

With thanks to those who helped the install go smoothly and quickly: